When it comes to new developments in printing technology, 3D color copiers are easily one of the coolest additions of the last decade. Obviously, the average office photo copier is not equipped with 3D printing capability, but 3D color copiers could become more affordable and more common as the technology is further developed. To prepare yourself for the next tech revolution, read up about 3D printing in this handy primer.

How does 3D printing in color copiers work?

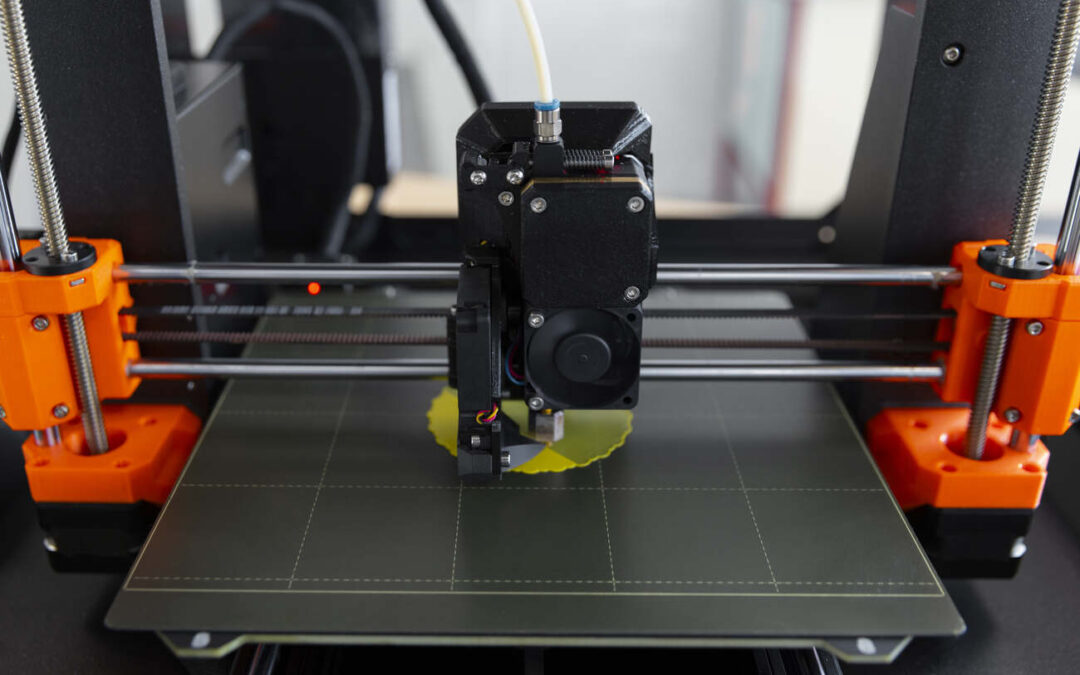

The idea behind 3D printing is deceptively simple. First, the user creates a virtual design of the desired object using specialized computer software. Once the design is complete, the object is printed using an additive process that lays down successive layers of material until the object is created from the ground up. The object may be made up of hundreds or thousands of thin slices, layered one on top of the other. Unlike a photo copier, which uses toner to create images, 3D printers use resins or other materials to create solid layers. Each layer is often dried using UV light, lasers, or similar processes.

What can be created with 3D printing?

Although the technology behind 3D printing is amazing in its own right, the ability to produce a wide range of objects is equally important. In the early days of 3D printing technology, many of the objects created were fairly simple things, like soap dishes, phone charging docks, business card cases, or even toilet paper holders. As the technology has become more widely accessible, it has been used in more important applications.

Pros & Cons

As with any new technology, 3D printing can be used positively or negatively. Using a 3D color copier is a great way for small companies to create the products they need while saving money by cutting out the middleman. Transportation costs, taxes, and general logistics expenses are all reduced when businesses can create components in their own lab. Reduced shipping also lowers the impact on the environment, not only by vehicles used to transport goods, but also by things like packaging materials. Printing in 3D also allows companies to test out small production batches to perfect prototypes without paying a third party to produce the items.

Only time will reveal the true abilities of 3D printing. This amazing technology could become a commonplace addition to the office color copier for many types of businesses and industries. If your business is involved in manufacturing or creative industries, 3D printing may be the wave of the future! Contact us for more information.

How 3D Color Copiers Are Transforming Healthcare, Education, and Small Business Innovation

While the current focus on 3D color copiers highlights the potential for creating physical objects, one aspect not often discussed is how these copiers are revolutionizing industries like healthcare and education. In healthcare, 3D printing technology is being used to produce custom prosthetics, dental implants, and even tissue scaffolds for regenerative medicine. This approach not only saves time and money but also ensures a personalized fit for patients. For educational institutions, having access to 3D color copiers allows students to bring their designs to life, fostering creativity and practical skills in engineering, design, and technology fields. This hands-on experience prepares students for future careers where 3D printing could become a standard tool.

Another exciting application is the ability to prototype quickly. Small businesses can now print multiple iterations of a product design, test them in real-world scenarios, and make improvements on the fly—all without needing a large production facility. This agility can be a game-changer for startups and creative industries looking to innovate on a tight budget. Not only does this reduce lead time, but it also minimizes the environmental impact by cutting down on wasted materials. As 3D color copiers become more affordable and efficient, they will likely become indispensable tools for businesses looking to stay ahead of the curve.

FAQ: 3D Color Copiers & Printing Technology

What are the benefits of using 3D color copiers in small businesses?

3D color copiers allow small businesses to quickly prototype products, saving both time and money. Instead of outsourcing to third-party manufacturers, companies can create prototypes in-house, speeding up the design process and reducing production costs. Additionally, these machines are perfect for small production runs, allowing companies to test multiple versions of a product before committing to large-scale manufacturing. Plus, the reduced need for shipping and packaging cuts down on both logistical costs and environmental impact.

Can 3D color copiers create complex objects?

Yes, 3D color copiers can create highly complex objects by layering materials one on top of the other. The layering technique means that intricate designs—like detailed architectural models or complex engineering prototypes—can be produced with relative ease. These objects are built layer-by-layer, allowing for precise customization and complexity that traditional manufacturing methods may struggle to achieve.

How is 3D printing in color copiers used in the medical field?

3D color copiers are revolutionizing the medical field, especially in the creation of custom prosthetics, dental implants, and even biological tissues. The ability to print personalized medical devices means patients receive tailored solutions that perfectly fit their anatomy. For instance, 3D-printed prosthetics are now more affordable and quicker to produce, improving accessibility and quality of care. Some studies show that 3D printing in healthcare could reduce costs by 30-50% in certain applications.

What materials are used in 3D color copiers?

While traditional copiers use toner or ink, 3D color copiers rely on various materials such as resins, plastics, metals, and even ceramics. These materials are layered to form a solid object, with UV light or lasers often used to harden each layer. Some advanced 3D printers are even experimenting with biodegradable or recyclable materials, making the process more eco-friendly.

Can 3D color copiers be used in education?

Absolutely! 3D color copiers have found a valuable place in education by providing hands-on learning opportunities for students in fields like engineering, architecture, and design. Students can turn digital concepts into physical objects, allowing them to experiment with real-world applications of their ideas. This approach enhances creativity and innovation while giving students practical experience with the latest technology, preparing them for careers in tech-driven industries.

What is the environmental impact of 3D color copiers?

3D color copiers can have a significantly positive environmental impact compared to traditional manufacturing processes. By enabling local production, these copiers reduce the need for transportation, which cuts down on carbon emissions. Additionally, the ability to produce on-demand reduces waste associated with overproduction. Some 3D printers are even utilizing sustainable materials like biodegradable plastics, further decreasing their ecological footprint.

How does 3D printing compare to traditional manufacturing methods?

Unlike traditional manufacturing, which often involves cutting away material to create a final product, 3D printing is an additive process. This means that material is only used where necessary, which significantly reduces waste. Furthermore, 3D printing is often faster and cheaper for small-scale production, making it ideal for prototypes and custom projects. It’s also far more flexible in terms of design capabilities, allowing for intricate and innovative shapes that traditional methods may not support.

What industries can benefit most from 3D color copiers?

Industries like healthcare, education, automotive, aerospace, and small-scale manufacturing stand to benefit the most from 3D color copiers. In healthcare, for example, 3D printing is used to produce custom medical devices. In education, students use 3D printers to bring their design projects to life. Meanwhile, automotive and aerospace companies use 3D printing to create prototypes of parts before mass production, reducing lead time and costs.

Are 3D color copiers expensive?

The cost of 3D color copiers varies significantly depending on the machine’s capabilities. Entry-level 3D printers for small businesses or educational purposes can start as low as $300, while more advanced, industrial-grade machines can run into the tens of thousands. However, as technology evolves and becomes more widespread, prices are expected to decrease, making these copiers more accessible to a broader range of industries and consumers.

Can 3D color copiers replace traditional office copiers?

While 3D color copiers offer exciting new possibilities, they are not a replacement for traditional office copiers. Standard color copiers remain essential for tasks like printing documents, making copies, and scanning images. However, 3D color copiers could become a complementary tool in offices, especially in industries that require frequent prototyping or design testing. It’s not a matter of replacement, but rather integration into the current office workflow.